Molded Rubber Parts Custom Designed And Supplied To Your Specific Needs

If you can imagine it, we can mold it. When it comes to molded rubber parts, Genesis Rubber can supply high quality parts with tight tolerances, custom designed to fit your application. We can also work with your existing molded part, and supply you with a reverse engineered part. No part is too complex and we can color match your part to pantone and RAL numbers based on your requirements.

Our molding capabilities include: Compression molding, transfer molding, and injection molding, as well as rapid prototyping.

An uncured elastomer preform is placed into a heated mold. The rubber is compressed between top and bottom plates (generally 2 plates but may contain 3 or more depending on part complexity and configuration) and the rubber part is vulcanized (cured) with heat and pressure (from compression).

An uncured elastomer is placed in a “transfer pot” located above the mold and the cavity. A piston transfers the uncured rubber into a pre-heated mold through a sprue, runner and gate system. The rubber part is vulcanized through heat and pressure.

The preheated mold is closed by a press which applies pressure to keep the mold closed during the injection and curing cycles. An uncured elastomer is injected into a heated mold by a large ram or screw. The elastomer is forced into the mold and its cavities through a runner, sprue and gate system.

Materials

Silicone

EPDM

Neoprene

Nitrile (Buna-N)

SBR

Viton

Fluorosilicone

Specifications

FDA / NSF

RoHS

UL

USP Class VI

ASTM

MIL Specs

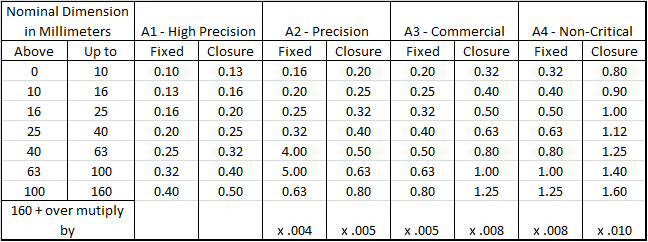

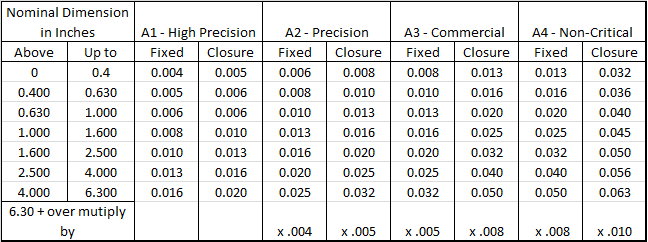

Our products are tested and inspected to strict RMA guidelines. This allows us to assure conformance to dimensional, flash and finish specifications, thus assuring the parts we deliver are of the highest quality.

RMA Tolerance Table For Molded Rubber Products

EPDM

Neoprene (CR)

Nitrile (Buna-N)

Silicone

Fluoroelastomer (Viton)

SBR

Natural Rubber

1(450)491-7707