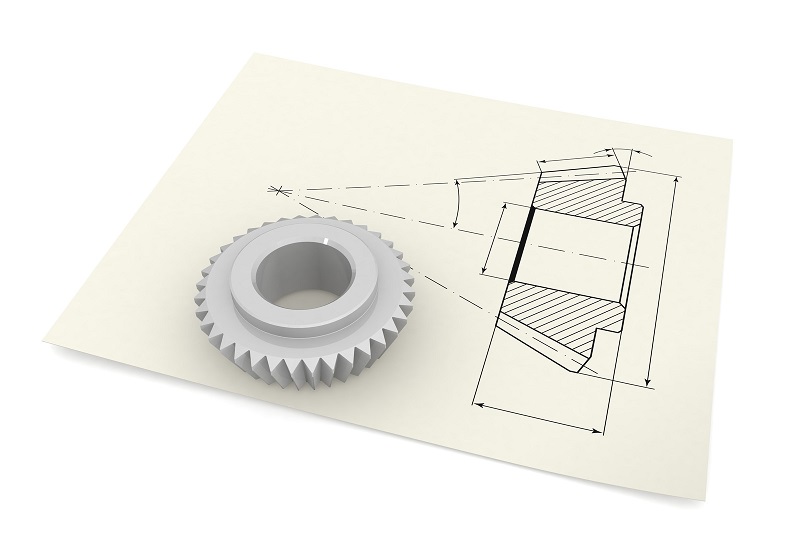

It isn’t always ideal using an existing, off-the-shelf rubber product and retrofitting it to your application. This often leads to gaskets and seals that once installed, fail in the field. These types of scenarios can leave you with a nightmare of replacements and cost overruns. Allow us to guide you from concept to product realization. Genesis Rubber can build a solution for you that will meet your sealing and specification needs. Smart design, innovative ideas and a sealing expertise that delivers a product tailored to your application.

Companies are often faced with the need to replace existing gaskets but lack the necessary drawings and specifications to do so. The process of replacing and replicating your specific seal or gasket can involve using an existing sample and identifying the right compound with the appropriate material specifications. Genesis can assist you with that. Our focus when it comes to reverse engineering is to provide a seal that fits your needs and to identify any areas for possible cost savings and design improvements. The result is a re-engineered product that suits your application, the way it was meant to.

Genesis offers the ability to set up product kits or

bundles as one master product using inventory planning and

control.

Customer specific labels, specific quantities per box (example 300pcs), and bagging and tagging.

EPDM

Neoprene (CR)

Nitrile (Buna-N)

Silicone

Fluoroelastomer (Viton)

SBR

Natural Rubber

1(450)491-7707